News | Management of Truck Chassis: 2016’s Final METRANS Research Seminar

Stop the VideoNews

METRANS UTC

Management of Truck Chassis: 2016’s Final METRANS Research Seminar

Thursday, December 15, 2016

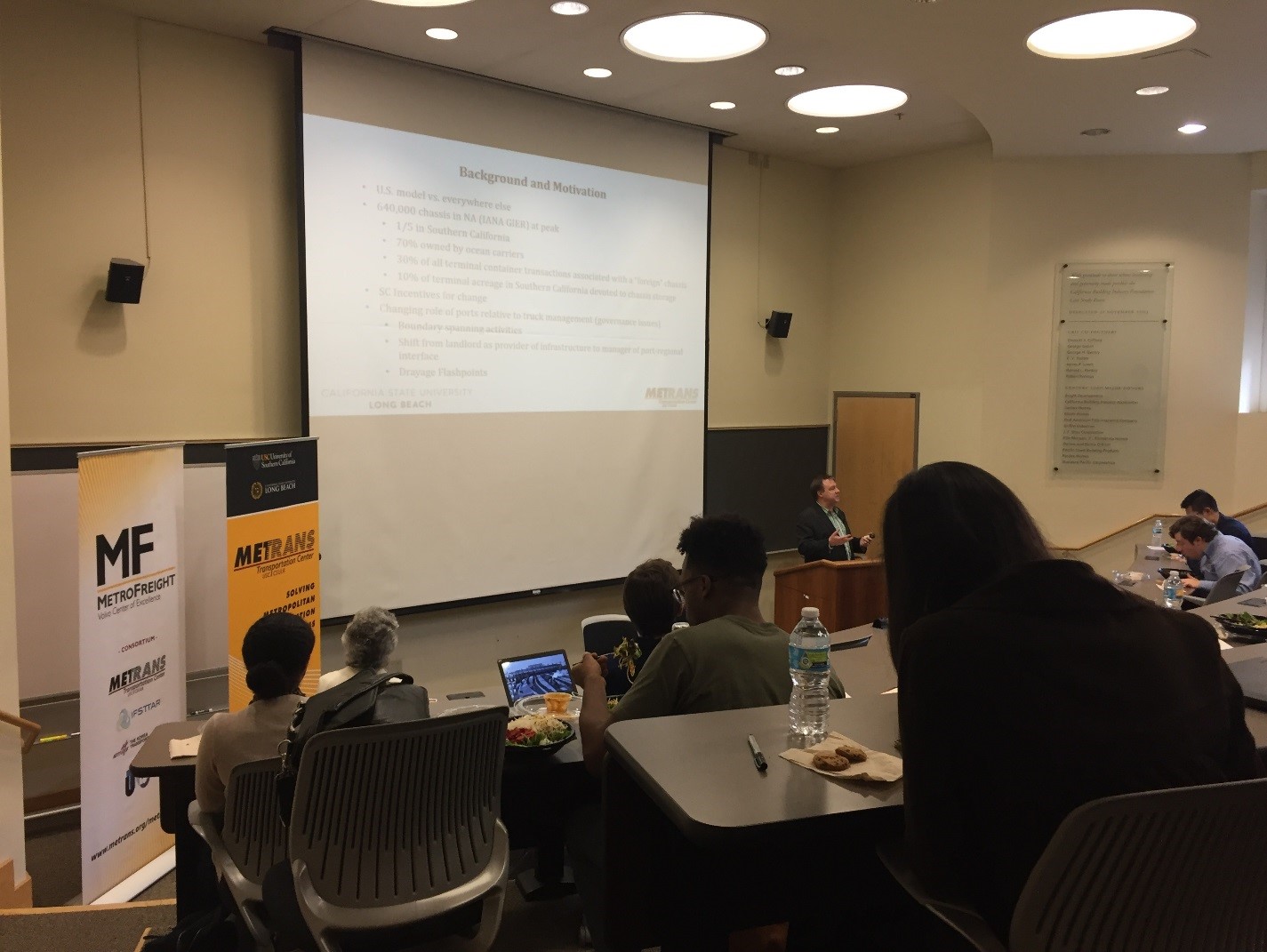

by By Tyler Linberg, MPL 2018

Photo by Kaitlyn Zhang

For the fall 2016 semester’s final METRANS Research Seminar, on November 16 Thomas O’Brien presented his work on examining possibilities for mitigating urban freight via the effective management of truck chassis, specifically highlighting lessons to be learnt from the “pool of pools” technique. A leading expert on freight transportation, O’Brien is Executive Director of the Center for International Trade and Transportation (CITT) at California State University, Long Beach CITT at CSULB, Associate Director of Long Beach Programs for METRANS, and Director of the FHWA Southwest Regional Surface Transportation Workforce Center (SWTWC).

O’Brien provided background information on current truck chassis management practices and why there is an incentive for change. While in the rest of the world chassis are owned by truckers themselves or by major retailers, in the United States they are owned by ocean carrier companies. This requires trucks to make trips back to the port terminals after dropping off freight—an inefficient process, especially when involving foreign chassis. Additionally, without the trucks being able to make multiple trips with the same chassis, they have to be stored between each use, taking up space at the port terminals. The inefficiencies lead to supply chain problems that are becoming more pronounced over time as larger container ships have met increased consumer demand and made efficiency in the supply chain more critical. For ports, the need for management of chassis exchanges has changed their role from providers of infrastructure to managers of the port-regional interface, leading the domain related questions . Finally, the Great Recession has left many ocean carriers with a surplus of chassis as trade slowed down gradually.

Together, these factors have pushed for a change in chassis management techniques, with the business model evolving among different companies to incorporate strategies such as a chassis usage charge, divestment of chassis, chassis pools, or some combination thereof. Chassis pools have been the most common management method chosen, particularly in Southern California, and are usually managed either by an ocean carrier company or by a terminal at the port. Terminal pools, though more common, haven’t been shown to make the supply chain more efficient. This is where O’Brien introduces the “pool of pools” at the Ports of Los Angeles and Long Beach, a cooperative of chassis pools that would allow any party with authorized users to have access to the chassis fleet managed by any pool within the cooperative.

It is this “pool of pools” that O’Brien studied to determine whether it can mitigate existing inefficiencies within the overall urban freight system. His prior research involved system mapping: tracking the movements of trucks engaging in various chassis transactions. This research solidified his notion that current chassis management techniques, without a cooperative pool of pools, have a negative impact on overall container performance, capacity, and emissions. With this research background, O’Brien then conducted system mapping of truck movements with a cooperative pool of pools management scheme. Various process flow scenarios were noted that could impact the results of the study differently, and then these scenarios were replicated to calculate the total number of truck movements made under each one.

Overall, the cooperative pool of pools chassis management technique was shown to reduce overall truck movements and mitigate some inefficiencies within the urban freight system, but it is important to note that different stakeholders acknowledge different benefits and drawbacks. Some trucking stakeholders feel it is a temporary solution, with broader challenges remaining in the chassis storage, roadability process, and the wider supply chain. Port Authority stakeholders theoretically have an interest in promoting competitiveness, which gives them a stake in improving intra-terminal chassis movements and transactions through the pool of pools. Rail stakeholders have noted that the pool of pools has helped prevent shortages when moving containers off of rail facilities, though rail operators have noted that identification of chassis owners has been made more difficult, a problem aimed to be solved by using technology to track equipment. Finally, intermodal equipment providers argue that the long-term sustainability of their operations depends on developing customer relations outside of the pool of pools, and are concerned more with land availability for chassis storage.

O’Brien concluded with possibilities for future research on chassis management practices. He primarily mentioned improving movement of chassis across terminals as well as movement of chassis to and from marine terminals and inland intermodal terminals along with the resulting impact on truck turn times. He concluded his presentation with the intriguing question of whether Hanjin’s bankruptcy will force American truckers into testing the waters with their own chassis.

Tyler Linberg

Tyler Lindberg is a second-year master of planning student with a transportation concentration. He currently interns in the Research and Analysis Department of the Land Use and Environmental Planning Division of the Southern California Association of Governments. He is particularly interested in how multimodal transportation can be tied with land use considerations to achieve various policy directives, such as congestion relief and greenhouse gas reduction.

News Archive

- December (1)

- November (6)

- October (4)

- September (2)

- August (3)

- July (4)

- June (3)

- May (7)

- April (8)

- March (11)

- February (8)

- January (7)

- December (7)

- November (8)

- October (11)

- September (11)

- August (4)

- July (10)

- June (9)

- May (2)

- April (12)

- March (8)

- February (7)

- January (11)

- December (11)

- November (5)

- October (16)

- September (7)

- August (5)

- July (13)

- June (5)

- May (5)

- April (7)

- March (5)

- February (3)

- January (4)

- December (4)

- November (5)

- October (5)

- September (4)

- August (4)

- July (6)

- June (8)

- May (4)

- April (6)

- March (6)

- February (7)

- January (7)

- December (8)

- November (8)

- October (8)

- September (15)

- August (5)

- July (6)

- June (7)

- May (5)

- April (8)

- March (7)

- February (10)

- January (12)